Deep Dive Resistors

Table of contents

How resistors shape your circuit. We can do circuit analysis with them all day long, yet we don’t understand what they do or their different types, leading to a lacking foundation with gaps of knowledge. It is very important for engineers to understand such basic concepts. In order for proper innovation, we must first have a solid foundation that leads to a creative mind with confident theories.

What is there to know?

There are plenty of things to know about resistors, but for our purposes, the key things to know are:

The types of resistors

The types of packages

The material and resistive processes

After diving into these topics, it will leave you with a very well-rounded view of resistors and all the factors to think about when creating.

Types

There are 3 main types of resistors. First being fixed value resistors. As the name suggests, these resistor values will always have the same values and cannot be changed. These are some of the most common types you will see, as they come in many different types of packages.

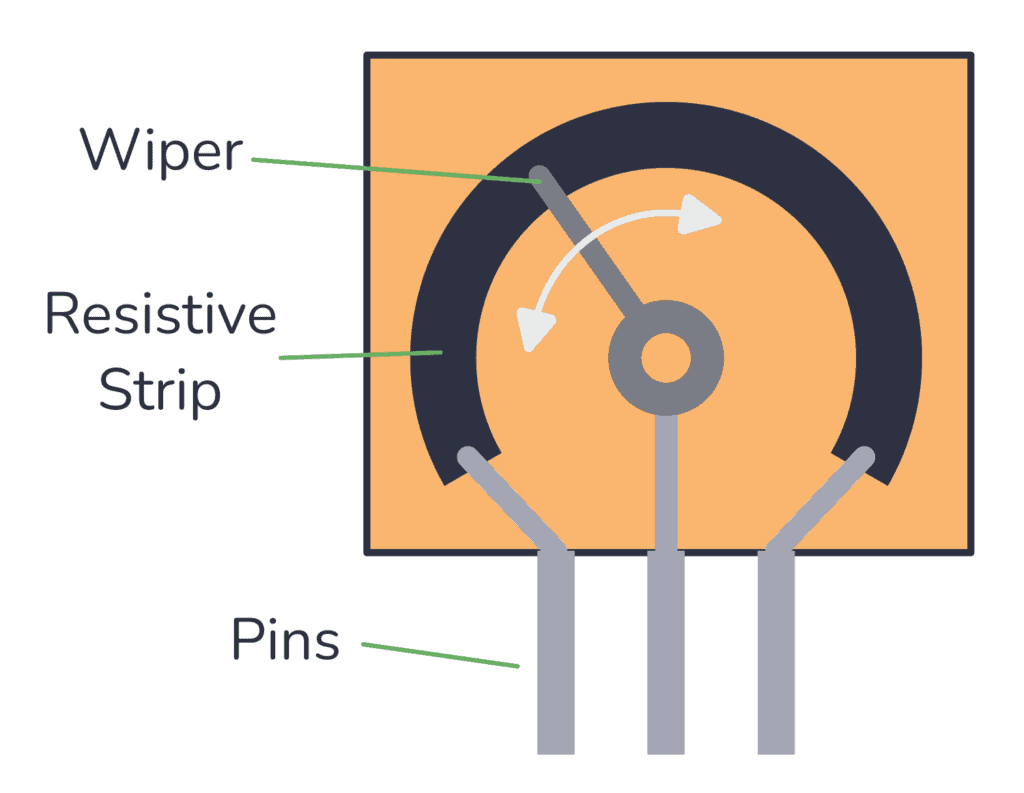

The second type of resistor is a variable resistor; again, as the name suggests, it is a resistor where you can change its value. There are 3 pins with this type of resistor as well, where the middle one is the output, the left is the input, and because of how they work, the right side is the ground. They function by spinning a rod, and that action changes the resistance. It changes the resistance by changing where the output touches the resistive material, as can be seen below in figure 1.

figure 1:

The final type that we will be going over is resistor networks. These basically are a bunch of fixed-value resistors put in a line. Their purpose is so often used for data bus applications. There are several variants of them, commonly being single inline (SIL) or dual inline (DIL) packages. For a deeper understanding, observe figure 2 below.

Figure 2:

They can also be packaged as a line of unconnected resistors like in figure 3.

figure 3:

Packages

There are 2 main types of packages for resistors, the first being through-hole. A through-hole resistor is a resistor where the connection points go through a hole to get soldered in place. The other type is a surface-mounted resistor. This may seem simple, but it is important to keep track of since not all resistors are able to be surface mounted. That is relevant since in industry they mostly use surface-mounted components as they take up less space and cost less to produce.

Materials and Processes

Here is the meat of it. This is where we will go over how each resistor actually resists.

Our first type will be a carbon film resistor. They are made by enclosing in a ceramic substrate. They are very simple but mostly phased out by our next material, metal film resistors. They have a couple of advantages, as there is a large cross-section allowing for higher voltages as well as leading to less induction; therefore, it is good at high frequencies as well.

As mentioned before, next we have metal film resistors. They are built the same, just with metal film instead of carbon film. These resistors are very similar to the carbon resistors but have more advantages. Advantages like less noise and way more precision.

Next we have metal oxide resistors. These again are similar to its predecessor. This type of resistor uses oxide as its resistance, often sourced from tin. Its advantage is it handles higher voltages and power better than metal film does. It also often has smaller ranges as well as reduced tolerances.

This next type is unique as it is more specialized for current measuring in power supplies. It is a metal strip resistor. They are very simple; it is just a very precisely trimmed strip of metal. Its key point is that it has low thermal resistance.

Finally we have wire-wound resistors. They are formed by wrapping a wire around an insulated core. They have a very low temperature coefficient and a very low tolerance, making them good for high-power applications. Since they are an inductor as well, they are not good for high-frequency applications. They are often not offered as surface-mounted as your other options are.

These are all important to keep in mind as you move and keep track of all their different uses. For more information and extra specs, check out this link. Stick around; your journey is just starting. Join the community and learn and grow with others @Wac.